Pages

Friday, March 18, 2011

TASK 3 - ECO REDESIGN (Kettle)

The product that we choose for the disassembly is an electric kettle. This product took us about 2 hours t0 dissamble it into parts. The hardest thing for us is to identify how many parts and to take out some of the parts due due to alot of many different fasteners that keeps the parts together.

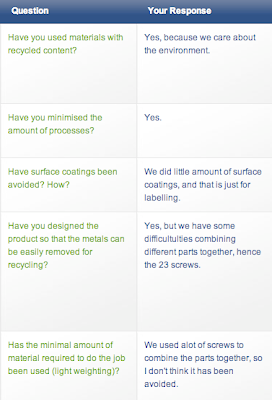

In this exercise we've identified the product materials and discussed the process of how the parts were made. This kettle predominantly uses material of Polypropylene. The design of this product is simple, although there is a challenge for us to take out the heating system due to this part having 8 screws, therefore making it harder for us to take it out. After the disassembly we found out that turns out all the materials of this product ended up have to go to landfill, that nothing can be really recycled which is such a waste and an indication of a non eco-friendly product.

The report from the greenfly shows that the part that has most environment impact is the heating system. (It took us a long time to separate it.) The result also shows that the design company didn't really consider the environmental impact this product could cause when they're designing the product, which is a shame, since a huge part of a good design is that it may be low in cost, but it still should be a bit sustainable at the very least.

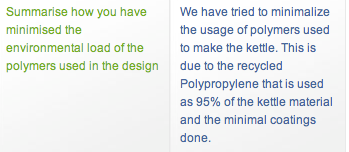

For redesigning this product we can make it more environmentally friendly by not using as much materials as it is. We considered reducing the requirements of using a large amount of fasteners, therefore most of the parts we can use self-locking techniques, and in this way,we'll be able to reduce the manufacturing cost and the product cost and also it will be easier for us to recycle the product, making it more environmentally friendly as well.

Group Members:

- Stanley Darmawan (Me)

- Susanna Li

- Guida Arezzi

- Jen Jun Zhu

- Katy

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment